E-mail :

blzzgg123@gmail.com

WhatsApp :

+86 13323926737

Model 1

| Model |

11FFG-90 |

||

| Size |

Tank diameter (mm):5500

|

||

| Minimum footprint(m²) |

55 |

||

| Tank volume(m³) |

86 |

||

| Capacity (m³) |

7-10/day |

||

| Output (m³) ( water content about 30%) |

3-4.5/day |

||

| Power |

380V 50HZ |

||

|

Model |

11FFG-102 |

||

| Size |

Tank diameter (mm):6000 |

||

|

Minimum footprint(m²) |

60 |

||

| Tank volume(m³) |

102 |

||

| Capacity (m³) |

8-12/day |

||

| Output (m³) ( water content about 30%) |

4-5.5/day |

||

| Power |

380V 50HZ |

||

| Model |

11FFG-160 |

||

| Size |

Tank diameter (mm):7000 |

||

| Minimum footprint(m²) |

70 | ||

| Tank volume(m³ |

160 |

||

| Capacity (m³) |

12-18/day |

||

| Output (m³) ( water content about 30%) |

5-7.5/day |

||

| Power |

380V 50HZ |

||

| Model |

11FFG-280 |

||

|

Size |

Tank diameter (mm):9000 |

||

| Minimum footprint(m²) |

100 |

||

| Tank volume(m³ |

280 |

||

| Capacity (m³) |

20-28/day |

||

| Output (m³) ( water content about 30%) |

8-12/day |

||

| Power |

380V 50HZ |

||

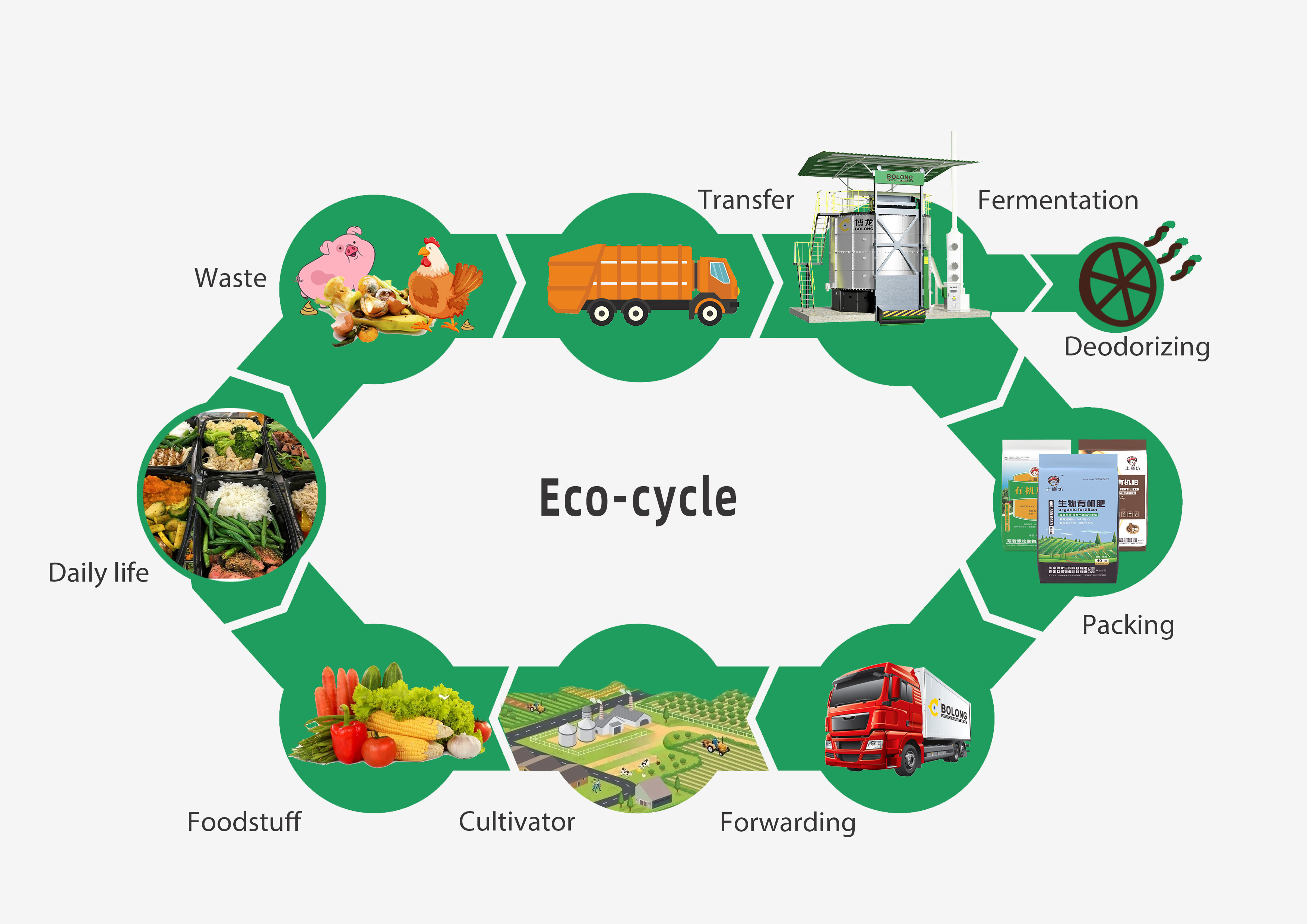

Stabilize plant growth and

reduce crop death

Increasing crop yields and

reducing the food crisis

Eliminates odours caused by ammonia and

reduces pollution of the surrounding air

Increasing nutrients in the soil

Contributing to the ecological cycle