Facing stringent environmental regulations and community concerns, a large-scale swine operation in Vietnam found itself at a crossroads. The traditional practice of open manure storage was no longer viable, creating operational bottlenecks and reputational risks. The farm needed a technology that could not only solve the pollution issue but also add tangible economic value.

Bolong’s integrated manure management system, with its high-temperature manure compost tank at the core, provided the definitive answer. This case study explores the technical journey and the transformative results achieved.

For intensive pig farms, manure is a constant byproduct. Conventional methods like lagoon storage or simple stacking are fraught with challenges:

Environmental Hazards: Risk of groundwater contamination and greenhouse gas emissions.

Regulatory Pressure: Increasingly strict laws against pollution and odor.

Economic Inefficiency: Wasting a potential resource that could be monetized.

Bolong’s philosophy is to view manure not as waste, but as a raw material. The solution centers on a systematic process that efficiently converts this material into valuable outputs.

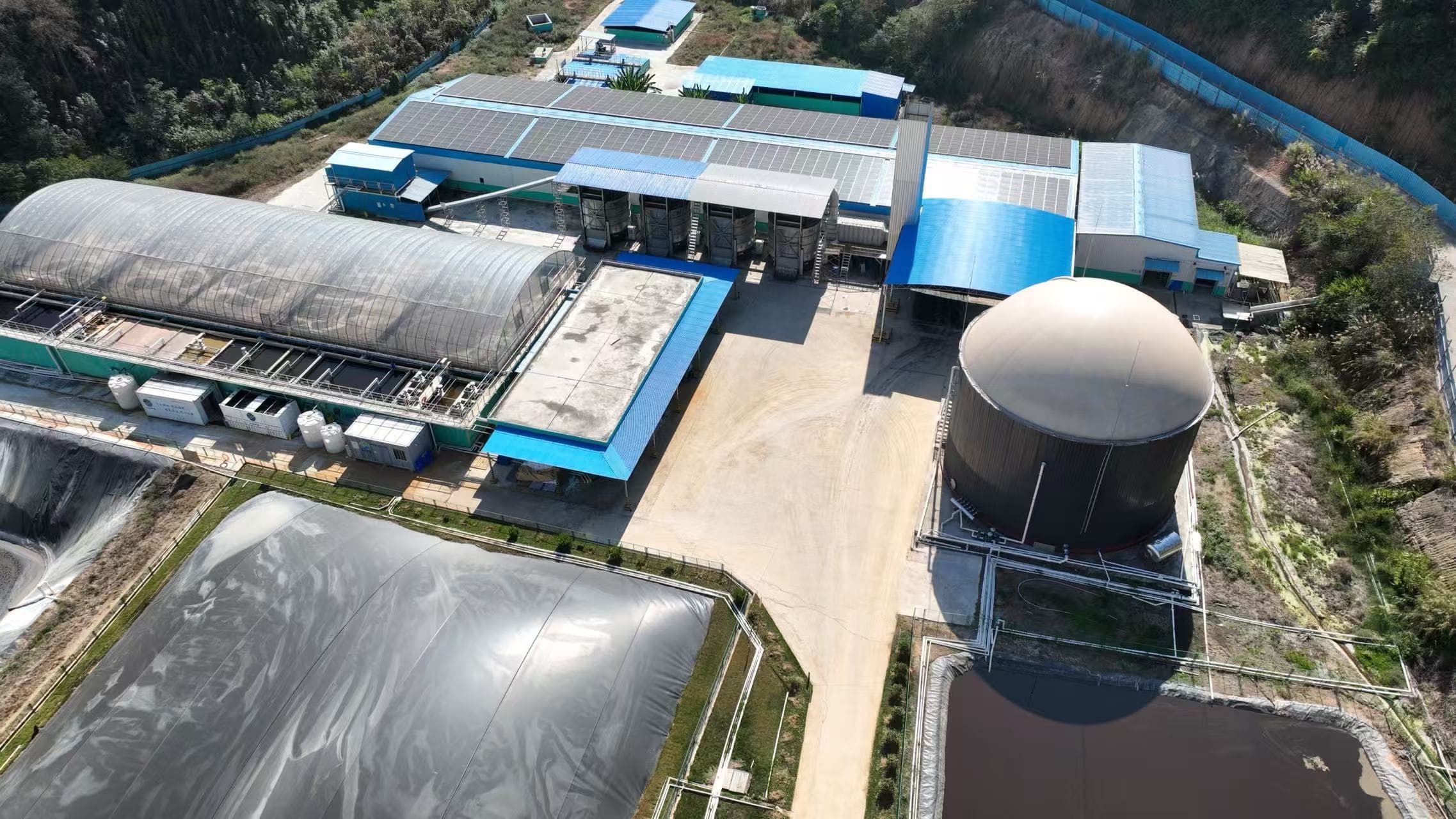

Bolong’s approach is a closed-loop system that addresses solid, liquid, and gaseous waste streams simultaneously.

The process begins with a high-efficiency solid-liquid separator. This machine acts as the first critical step, dividing raw manure into two distinct pathways:

Solid Fraction: The nutrient-rich manure material is immediately conveyed to the manure compost tank for primary processing.

Liquid Fraction: The wastewater is channeled into a dedicated treatment system for further purification.

The manure compost tank is the heart of the resource recovery process. Here, the solid fraction undergoes high-temperature aerobic fermentation.

Sealed & Automated Environment: The fully enclosed tank maintains optimal temperature and humidity, accelerating microbial activity.

Rapid Transformation: Within just 7 days, the material is converted into stable, high-quality, and pathogen-free organic fertilizer.

Odor & Emission Control: An integrated biofilter or deodorization system neutralizes unpleasant odors (ammonia, hydrogen sulfide), ensuring neighbor-friendly operation.

The system’s intelligence lies in its synergy. The liquid portion undergoes multi-stage sedimentation and aeration, producing clean water suitable for irrigation. Meanwhile, biogas captured from the entire process can be purified and used to power the facility, creating an additional layer of energy independence and cost savings.

Tangible Outcomes: Compliance, Profit, and Sustainability

By adopting Bolong’s system, the Vietnamese farm achieved a triple-bottom-line success:

Regulatory Compliance: The farm fully met local environmental standards, eliminating the risk of penalties.

Economic Gain: The organic fertilizer produced by the manure compost tank became a new revenue stream, sold to local growers seeking sustainable soil amendments.

Enhanced ESG Profile: The solution significantly reduced the farm’s environmental footprint, improving its community relations and brand image.

This case demonstrates that modern agricultural challenges require intelligent, resource-oriented solutions. Bolong’s manure compost tank proved to be more than just a piece of equipment; it was the pivotal technology that enabled a complete shift from a linear “take-make-waste” model to a circular, profitable, and sustainable operation.

For pig farms seeking to future-proof their operations, investing in a manure compost tank system is a strategic move toward environmental stewardship and economic resilience.